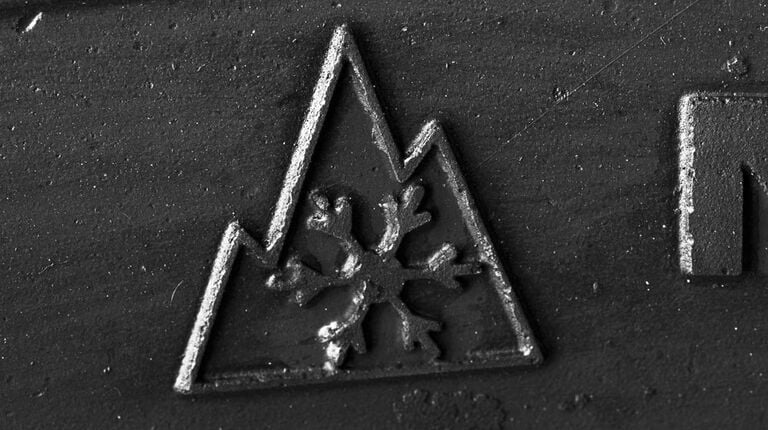

What does the Mountain Snowflake Symbol on winter tires mean?

How can you tell if a tire is certified as road worthy to handle a Canadian winter? Just look for the made-in-Canada severe service symbol on the sidewall of your winter tires and true all-weather tires.

Indicated by a pictograph showing a peaked mountain with a snowflake in the middle, the severe service symbol indicates a winter tire can handle snowy and slippery roads, as well as low temperatures, and meets the minimum requirements for providing snow traction.

How winter tires earn the Mountain Snowflake symbol

In the 1990’s, the U.S. Rubber Manufacturers Association and the Tire and Rubber Association of Canada (TRAC) sought a way to help drivers identify tires that were designed to perform in severe snow and cold weather conditions.

In 1999, they came up with a snow traction test that winter tires must pass in order to receive what we now know as the severe service emblem—the snowflake on the mountain peak.

If you drive in icy, cold conditions, Transport Canada and the Rubber Association of Canada recommend installing winter tires bearing the mountain snowflake symbol on all four tires for best vehicle handling.

How winter tires are tested

Winter tire testing standards are defined by the American Society for Testing and Materials (ASTM). Tire manufacturers can conduct these tests themselves, or hire a private testing company to do it for them. Manufacturers use the results from these tests to determine whether they can brand their tires with the mountain snowflake symbol.

To make sure tires are working at their best, a testing facility will simulate the conditions where winter tires are used. They will look at the:

- Air temperature: The rubber compound of summer and hardens at +7 C. Winter tires contain a special rubber compound that keeps them soft and flexible in extreme cold.

- Snow temperature: The temperature must be between –15C and –3C for optimal testing conditions.

- Consistency of the snow: Medium pack snow—neither hard-packed nearing icy, nor too soft and powdery—really puts winter tires to the test for snow traction because the tread can bite into it. If need be, the test team will use specialized snow preparation tools to move snow around and break it.

Where you won't find the symbol

Tires marked M+S (mud and snow), also known as 3-season tires, don’t have the severe service symbol. That’s because 3-season tires are safe for most conditions, but they’re not designed to give grip on ice or in sub-zero weather.

In fact, 3-season and summer tires become hard at temperatures below +7 C, leaving you with reduced traction and unsafe handling. The severe service symbol was created to distinguish winter tires from 3-season tires.

Other types of tires where you can find the Severe Service Symbol

Did you know there are also all-weather tires and all-terrain tires that are marked with the peaked mountain and snowflake symbol?

All-weather tires are a designated winter tire that doubles as a reliable summer tire—a true year-round tire that saves you the hassle and expense of storing a second set of tires. Learn more in our article What’s the difference between all-season tires, all-weather tires and winter tires?